Use requirements: The performance and effect of the anti falling safety device of the construction elevator directly affect whether the construction elevator can be used safely. In order to ensure the effectiveness of the anti falling safety device, regular inspection is essential. What are the specific requirements of the national standards for the inspection period and service life of the anti falling safety device of the construction elevator? According to the construction industry standard of the peoples Republic of China construction elevator gear cone drum progressive anti falling safety device (jgl21-2000), construction elevator anti falling safety device can only be used within the valid inspection period. The valid inspection period of the safety device shall not exceed two years. Whether the safety device is used or not, it must be re calibrated after the expiration of the effective inspection. These safety measures are to ensure the safe use of construction elevators and prevent safety incidents. (gb10055-2007 safety regulations for construction elevators 11.1.9 stipulates that the anti falling safety device can only be used within the valid calibration period, and the valid calibration period shall not exceed one year. ) Detection protection: In order to ensure the safety of the construction elevator, we must verify the anti falling safety device every 1-2 years. What verification equipment and items should be used in the verification of the anti falling safety device? According to the understanding of Dacheng Construction Machinery Co., Ltd., at present, the test-bed for the inspection and calibration of the anti falling safety device generally needs the performance tester, stepless speed regulating device, torque and speed sensor, microcomputer type torque...

In recent years, Chinas reducer industry has benefited from the continuous deepening of industrialization and urbanization process and the attention of the state to the machinery manufacturing industry. As one of the basic equipment industries in China, the reducer industry is one of them. After more than 40 years of market development, the reducer products have also developed from the original single cycloid reducer to the present gear reducer, worm reducer, etc., and are widely used in various fields of national economy, such as electric machinery, metallurgical machinery, environmental protection machinery, chemical machinery, food machinery, mining machinery, construction machinery, water conservancy machinery, etc., which are popular in the city Field favor. Reducer industry Driven by the national macro-control, Chinas reducer industry has gradually developed into the main battlefield of the international reducer industry. World famous enterprises have entered the reducer Market in China, and with the advantages of excellent brand, abundant capital, advanced technology and equipment, they have launched fierce competition with domestic reducer enterprises. However, domestic enterprises mainly engaged in the production of general purpose reducers have less involvement in the field of industrial special reducers and immature industrial technology. Therefore, in the competition with foreign advanced enterprises, if Chinas reducer industry wants to occupy the leading position in the market competition, it will take a long time for the market to hone. The slow recovery of the world economy makes the global consumer market active again. At the same time, the appearance of the effect of Chinas macroeconomic policies and the continuous strengthening of the investment in inf...

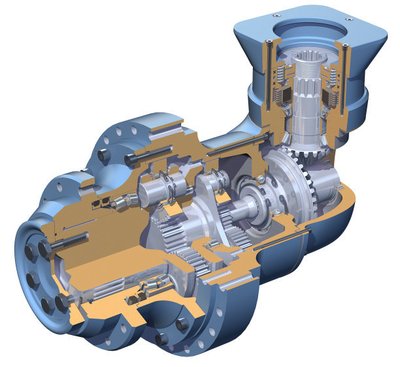

How to check and maintain the reducer effectively. Do not mix different lubricants. The position of the oil level plug, drain plug and breather is determined by the installation position. Their relevant positions can be determined by referring to the installation position diagram of the reducer. The following is mainly through oil replacement, oil level inspection, for the reducer with oil level plug, oil inspection and other aspects to elaborate. 1、 For reducers with oil level plug Check whether the oil level is qualified; install the oil level plug. 2、 Oil change It is difficult to drain oil when the viscosity of oil increases after cooling, so the reducer should change oil at operating temperature. Cut off the power and prevent electric shock! Wait until the reducer cools down and there is no danger of combustion! 3、 Precautions Inject new oil of the same brand; the oil volume shall be consistent with the installation position; check the oil level at the oil level plug; tighten the oil level plug and the ventilator; keep the reducer warm when changing the oil; place an oil pan under the oil drain plug; open the oil level plug, the ventilator and the oil drain plug; drain all the oil; install the oil drain plug. 4、 Inspection of oil level Cut off the power and prevent electric shock! Wait for the reducer to cool down; remove the oil level plug to check whether the oil is full; install the oil level plug. 5、 Oil inspection Cut off the power and prevent electric shock! Wait for the reducer to cool down; open the drain plug and take the oil sample; check the viscosity index of the oil; if the oil is obviously turbid, it is recommended to replace it as soon as possible. More information welcome to Nantong Shuanglu construction machinery factory. Welcome new and ...